Non-Destructive Testing for Investment Castings

Non-destructive testing (NDT) is performed to verify structural and mechanical soundness and find surface and sub-surface defects that may impact the efficacy of a casting. The defects, including small cracks, tears and voids, are invisible to the naked eye and therefore cannot be detected by conducting a standard visual inspection.

The use of non-destructive testing for investment casting helps ensure compliance with defined quality standards, which is especially important for aerospace, military and defense, and end users where investment cast parts are created for use in critical applications. If defects are identified, Engineered Precision Casting has the capability to weld with contract approval.

NADCAP Accredited Services for Non-Destructive Testing

Engineered Precision Casting Co., Inc. is NADCAP accredited for nondestructive testing operations including liquid penetrant inspection, magnetic particle inspection and radiographic inspection. Our personnel are also qualified and certified to various customer requirements and aerospace industry standards such as NAS-410. Training programs, compliance audits, process controls, detailed procedures, and techniques round out a special process program that is dedicated to quality.

All our non-destructive testing for investment casting is performed in-house for improved quality to control and to help reduce costs and lead time. Learn more about the different services we offer or contact us to discuss non-destructive testing for investment castings.

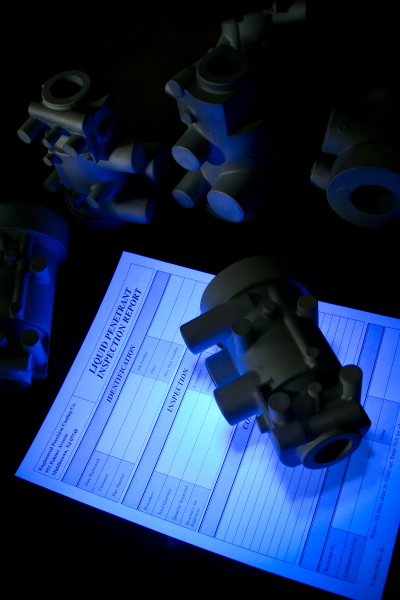

Liquid Penetrant Inspection for Investment Casting

Liquid penetrant inspection is used to find small tears, cracks, voids or porosity on the surface of a casting that would otherwise be difficult to find with the naked eye. The process involves cleaning a part, then coating it with a colored liquid penetrant. The part is then lightly cleaned to remove the excess and a developer is applied to the surface. The developer draws the dye out of the defect areas to make them more visible. A UV or visible light is then used to examine the part surface and findings are recorded.

Liquid penetrant non-destructive testing is safe for ferrous and non-ferrous investment cast parts. It is an excellent and effective solution for detecting porosity and other surface defects, but it will not detect the presence of flaws in the sub-surface of a part.

Magnetic Particle Inspection for Investment Casting

Magnetic particle inspection (MPI) is used to inspect the surface of investment cast parts for defects or inconsistencies such as small tears, voids and cracks on the surface. It involves using AC or DC electrical currents to pass a magnetic field through the part. Any cracks or other defects on the surface or sub-surface contain air that will cause the magnetic flux to leak, allowing the defects to be detected.

The magnetic particle inspection method is highly effective for finding surface cracks. Since it involves the use of magnetic fields, however, it will only work for ferromagnetic materials and alloys containing iron, cobalt or nickel.

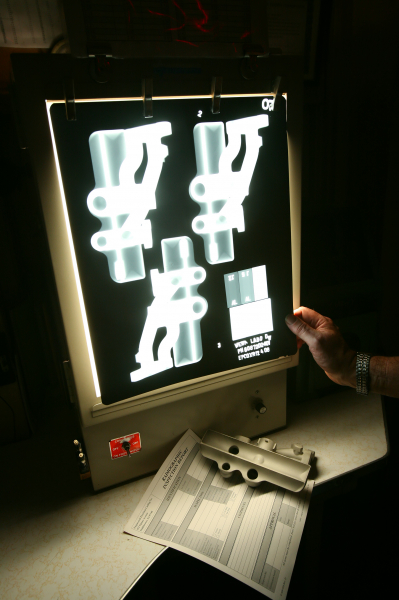

Radiographic Inspection for Investment Casting

Radiographic inspection involves the use of X-rays to inspect investment cast parts internally for cracks, voids, porosity and other defects. During the testing process, the castings are exposed to radiation to produce a radiographic film. The film is then visually inspected for darkened areas, which indicate the presence of a defect in the part.

Radiographic non-destructive testing can be used for ferrous and non-ferrous metals and is best suited for finding sub-surface defects in investment castings.

Learn More About Non-Destructive Testing for Investment Castings

Engineered Precision Casting Co., Inc. provides NADCAP accredited non-destructive testing and other secondary services as part of our investment casting process. Contact us today to learn more about our investment casting capabilities and to discuss your project.