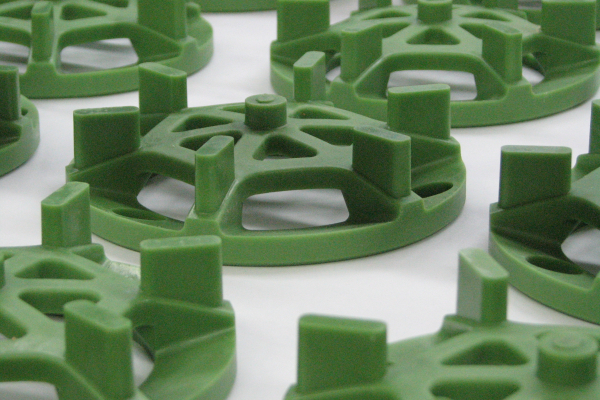

Size & Dimensional Tolerances

Size and dimensional tolerance are important considerations in deciding whether investment casting is the right solution for your project. Tolerance is determined by the size and shape of a part and includes both linear and geometric considerations such as:

- Length

- Concentricity

- Roundness

- Parallelism

- Perpendicularity

- Flatness

- Straightness

- Angularity

What Dimensional Tolerances Can Be Achieved with Investment Casting?

Size and shape are the main factors in determining geometric and linear tolerances. For projects that require strict tolerances, investment casting is an excellent option as it produces parts with great accuracy and repeatability.

Engineered Precision Casting Company has experience investment casting parts for aerospace and other industries that require a high level of precision and accuracy. We provide investment casting for part sizes up to 16 x 16 in. and 40 lbs. and with the following industry standard dimensional tolerances:

| Linear Tolerances: ± .010 up to two inches (2”) ± .005 per each additional inch |

Angularity: ± 1/2 ° |

|

| Flatness & Straightness: ± .003 to .005 per linear inch |

Surface Finish: 100 RMS |

|

| Parallelism and Perpendicularity: ± .003 to .005 per linear inch |

Concentricity: ± .003 to .005 per linear inch |

It is important to fully discuss your part size and dimensional requirements with your investment casting company. If you have questions regarding your project, our team of experts can review your print to determine whether your required tolerances can be achieved through investment casting.

Contact Us to Discuss Your Investment Casting Size and Tolerance Requirements

We provide investment casting for a range of industries and have the expertise to achieve tight tolerances. Engineered Precision Casting Company also provides a wide selection of casting materials to accommodate a range of application requirements. Contact us today to discuss your dimensional tolerance requirements.